Dematic Awarded a Major Contract from the Automobile Supplier ZKW

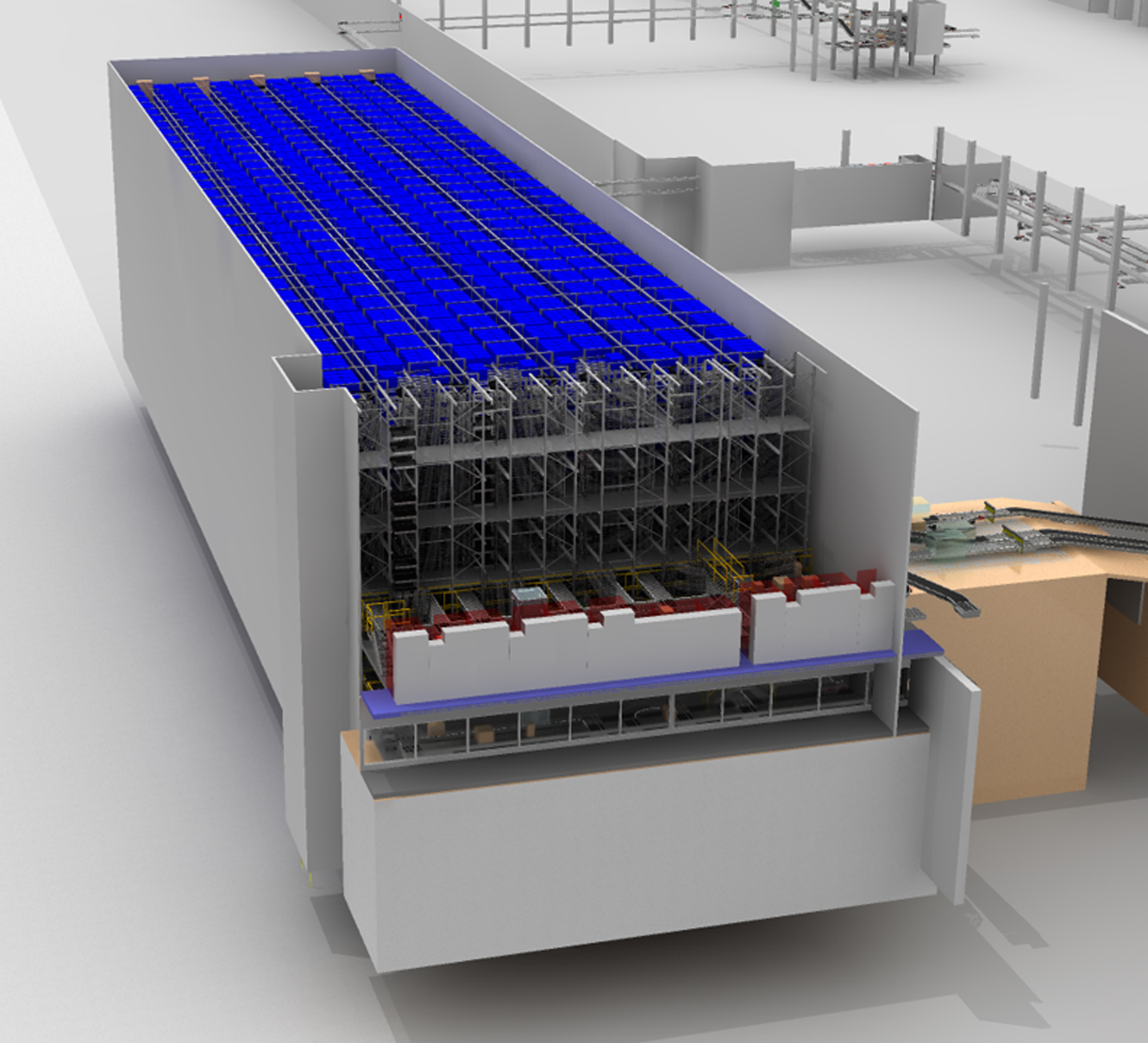

Dematic automates the new logistics centre of ZKW Lichtsysteme GmbH and installs a custom-made Dematic Multishuttle warehouse in silo design. (Image: Dematic)

2020-02-12 / 10:36:14

- Intralogistics specialist automates new logistics centre in Austria

- Dematic Multishuttle with 62,220 container spaces

- Automated conveyor system connects warehouse and production

Heusenstamm / Wieselburg (Austria), 12. February 2020 – Dematic is automating the new logistics centre of ZKW Lichtsysteme GmbH. Because their previous storage areas were no longer sufficient, the automotive supplier is constructing a new production supply build-ing at its headquarters in Wieselburg (Austria). To make optimum use of the site's capacity, the intralogistics specialist is installing a custom-made Dematic Multishuttle warehouse in a silo design with over 60,000 container spaces, which will allow for efficient, multiple-depth storage of headlamp components. There will be 140 shuttles automatically accessing the containers in the storage system and transporting them directly to the workstations for palletising before continuing to the incoming and outgoing goods areas. In addition, the three kilometre-long conveyor system transports the compo-nents fully automatically through the factory to the production area. In this way, ZKW Lichtsysteme will be able to increase its through-put rate up to 1,500 containers per hour. Construction of the plant is scheduled to begin in the third quarter of this year. The ultra-modern logistics centre is scheduled to go into operation in the second half of 2021.

"With our intelligent, flexible and high-performance intralogistics system at ZKW Lichtsysteme, we are able to ensure efficient material supply be-tween warehouse and production," says Jessica Heinz, Head of Marketing and Business Development Dematic Central Europe. Due to their increas-ing variety of products and the resulting more complex intralogistic pro-cesses, ZKW Lichtsysteme decided to implement an extensive automation of their material flow. At its main plant, the active global system supplier for the automotive industry produces around three million main headlamps per year and numerous spare parts. One of their greatest challenges is to keep the various components for production in line with demand.

"Because of its high degree of automation and compact design, the Dematic Multishuttle with Flex technology is ideally suited to the require-ments of ZKW Lighting Systems, allowing containers of different sizes to be dynamically stored," says Heinz. The system also ensures fast and re-liable order processing.

To optimise the cycle-controlled supply of the production lines, the system will integrate a station for container cleaning and a route train for load handling. Dematic's SAP experts will be responsible for integrating with the IT structures of ZKW Lighting Systems. They will also ensure that both the administration of the Dematic Multishuttle and the material flow are man-aged directly in the SAP Extended Warehouse Management (EWM) sys-tem. No additional systems are required. Similarly, an innovative light pointer system will be used to guide employees during the distribution of containers to the assembly shelves from the SAP EWM.

For further information about Dematic GmbH, go to www.dematic.com/de

About Dematic:

Dematic is an intralogistics innovator that designs, builds and supports intelligent, automated solutions for manufacturing, warehousing and distribution environments. Its customer base includes some of the world's leading brands which are driving the future of retail with Dematic installations. Dematic's global network of development centres, manufacturing and service facilities with over 8,000 employees in more than 25 countries has helped to realise more than 6,000 customer installations. Headquar-tered in Atlanta, Georgia, USA, Dematic is a member of the KION Group, a global leader in warehouse automation, material handling equipment, supply chain solutions and related services.

Contact for Journalists and Editors:

Jessica Heinz

Dematic GmbH

Head of Marketing und Communications CE

Martinseestr.1

63150 Heusenstamm

Tel: +49 (0)69 583025 125

Mobil: +49 (0)172 65 98 590

Fax: +49 (0)69 8903-1840

jessica.heinz@dematic.com

www.dematic.com/de