Who we are

Batteries are the future and they are built by us

As KION Battery Systems - a joint venture between KION GROUP AG and BMZ Holding GmbH - we produce various types of lithium-ion batteries for industrial trucks in Karlstein am Main (Germany).

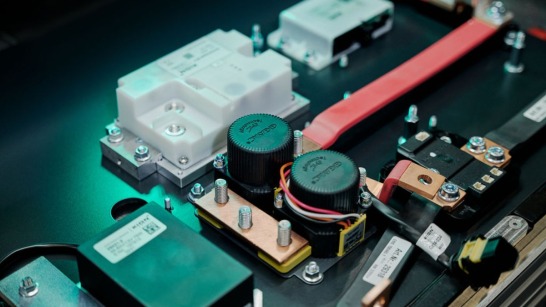

With precision, high safety standards, and state-of-the-art technology, the batteries assembled at KION Battery Systems are of outstanding quality. And pave the way into an electric-driven, sustainable future.

That's what we stand for

Our Services

Design

Our research and development team creates state-of-the-art battery solutions and provides our customers with solutions for their individual operational needs.

Production

Our production focuses on manufacturing high-performance batteries that provide an average of more than 2,500 charging cycles, equivalent to more than 10 years of useful life.

Refurbishment

Once batteries reach their period of use life or experience other damage, we offer refurbishment services. According to a sustainable life-cycle we bring new life into old batteries and bring them back to as-new condition.

Our Employees

Across all departments everyone is really supportive and helps me in any way they can to finish my thesis, I really feel in good hands here.

Yasemin Sanli’s journey at KION Battery Systems started with an internship she completed during her master studies of industrial engineering. After that she joined the research and development team to tackle her thesis – and dive deeper into the myths of batteries and logistics. “Logistics in general has taken on a new significance in the past years and has been put into the spotlight”, says Yasemin Sanli. “In this context, batteries represent a key technology for future-proof, reliable supply chains which is why I am taking a great interest in this subject here at KBS.”

Regarding her daily tasks, she has already received great appreciation also as a young colleague who is still in training and has been able to demonstrate her skills in several projects in close collaboration with BMZ. This allowed her to gain a wide range of insights into other areas as well. Currently, she collects information for her master thesis on the topic of modular battery systems – with great help of her boss at R&D. “Across all departments everyone is really supportive and helps me in any way they can to finish my thesis, I really feel in good hands here.”

I really like working so closely together with people in this rather technical environment and at the same time it is really satisfying to feel that your work has a real impact, literally in the form of a fully assembled battery.

Tobias Barbier has an impressive career path to show: he started out as an operator at joint venture partner BMZ and quickly became production coordinator compiling work instructions and taking care of the labels. When he switched to KION Battery Systems, he moved to production setter taking on more responsibility of the staff. “I really like working so closely together with people in this rather technical environment and at the same time it is really satisfying to feel that your work has a real impact, literally in the form of a fully assembled battery”, says Tobias Barbier. And he does not rest on his laurels: currently, he completes a training as industrial foreman.

For him, KBS offers the unique opportunity to grow together with the company. This means that hierarchies are extremely flat, and he is able to directly represent his team and its visions to the board. “The combination of the longstanding know-how located at BMZ and the young spirit at KION Battery Systems provides a great working environment – and on top of that, batteries are the future.” For his personal future, he wishes to further deepen his knowledge on the subject and to continue to be a highly appreciated trustee for his team.

The process of manufacturing lithium-ion batteries and the technology that accompanies this process have an enormous potential for the future which is why I am very keen to streamline these developments here at KBS.

With an intensive background in mechanical engineering, Dr. Deborah Schmidt had a great foundation to build on when she joined KION Battery Systems in December 2020 as project leader research and development lithium-ion batteries. Then, she had just finished her dissertation on internal combustion engines at the technical university Darmstadt, located just 40 kilometers from the KBS headquarters in Karlstein am Main. This in-depth knowledge helped her to quickly dive deep into the subject and familiarize herself with every aspect revolving around batteries.

“The process of developing lithium-ion batteries and the technology that accompanies this process have an enormous potential for the future which is why I am very keen to streamline these developments here at KBS”, says Dr. Deborah Schmidt. As a team leader since January 2022, leading a team of seven, her responsibilities include ensuring the entire development process from concept studies to production readiness as well as the coordination of the project teams. Her motivation: to foster a creative work environment that challenges her colleagues to develop new approaches in this fascinating field and guarantee a dynamic growth process that further evolve the battery business at KBS.

Join us!

We are a member of the international KION Group and are looking for new employees. Use the link to find our job opportunities at KION Battery Systems.

Code of Compliance

The KION Group Code of Compliance contains the rules that govern the way we do business at KION Battery Systems. For that is what compliance means: abiding by laws and company policies.

The following link guide you to the KION Group Code of Compliance on the KION Group website.

Contact

KION Battery Systems GmbH

Zeche Gustav 1

63791 Karlstein am Main

Germany

Phone +49 6188 9929 0

info@kion-batterysystems.com

The KION Group

We employ more than 42,000 people and are among the world’s leading suppliers of industrial trucks and supply chain solutions. Our portfolio encompasses forklift trucks and warehouse trucks, as well as integrated automation technology and software solutions for the optimization of supply chains, including all related services.