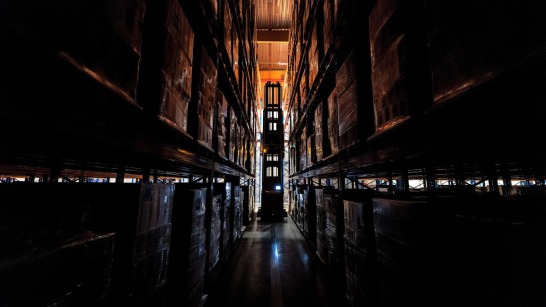

The Future of Logistics: How Automation is Revolutionizing Supply Chains

More automation – that’s what every warehouse operator wants. From intelligently linked subsystems to fully automated facilities: How Linde Material Handling and Dematic implement comprehensive performance improvements in the warehouse through shuttle systems, AGVs/AMRs, AutoStore™, WMS/WCS, and AI driven orchestration.

2025-08-13