At the 19th Industrial Truck Conference held this past September in Baden, Baden Germany, Stefan Prokosch noted that “today’s customers are interested in performance and not in the underlying technology.” The head of product management for counterbalance trucks at KION brand Linde Material Handling called on his fellow participants to be “more closely integrated with customers, better understand their processes, yet still be willing to learn so that we can do a little better each and every day.”

Manufacturers, researchers, suppliers and customers from the material handling and intralogistics industry participated in the 2-day biannual VDI - the Association of German Engineers - conference to get a better undertanding of where the industry is heading. The event provides an opportunity to introduce new products and services and discuss the latest trends. “You compare notes without revealing any trade secrets, of course,” is how Heiner Sternstein, the head of Industrial Trucks Development at Linde MH and the conference chair, describes it. “And it’s always helpful when manufacturers can get feedback from operators.”

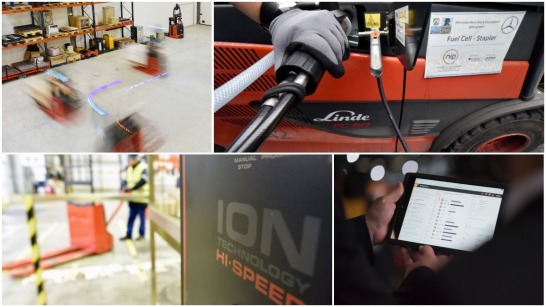

A lithium-ion future

Powertrains and drive technology were a hot topic this time. Ottmar Neuf, the director of development engines at KION Group, questioned whether diesel still had a future in industrial trucks. “For now, the answer is yes, but mainly in traditional, heavy-duty applications and in countries whose emissions standards are not so stringent," he said, adding,"But major advances have been made in lithium-ion batteries and they are now a serious alternative; even when they are used in heavy-duty trucks for transporting large loads.”

Joachim Hirth, who works in Innovation & Technology at Linde MH, held a detailed presentation on the various types of lithium-ion batteries and the prospects for improving them. In the trade-off triangle between energy output, safety and longevity, developers have always made concessions in at least one area. But Hirth noted that research is already beginning to offer solutions. “Many of these innovations are in the very early stages of development, but we will begin seeing others implemented in the next five years.”

A mix of drive technologies ahead

In contrast to alternatives such as lead-acid batteries, lithium-ion batteries do not need to be replaced, which is one of the main reasons why they are currently receiving so much attention. Hirth and his Linde team have worked out that “if the trucks are charged smartly, they can easily be used in a 2-shift or 3-shift operation.”

“We also want to eliminate the need for battery changes,” said Matthias Kromm, a technical planner at Daimler AG, offering a user perspective. In June 2015, Kromm’s plant in Düsseldorf began a long-term trial of fuel-cell trucks, including ones from Linde. “They are still in operation; it’s working well,” reported Kromm, who was particularly taken with how quickly and safely the fuel cells could be refueled, not to mention the fewer number of work steps involved when compared with the changing or charging of batteries. Going forward, industry experts believe that there will continue to be a mix of drive technologies to meet various requirements, though the trend may shift towards innovative technologies such as lithium-ion and fuel cells.

Automation, connectivity and drive technologies and the extent to which these future-focused topics overlap and interact came up repeatedly during the conference.

It’s no surprise that many of these innovations play a role in wider global megatrends, as Prokosch identified in his future-focused presentation. He said that urbanization, globalization and greater mobility mean that even now, and not just in tomorrow's warehouses, it is possible to process increasingly large volumes of goods at much faster speeds and in increasingly smaller package sizes.

“In many areas, we are well on the way to fully automated warehouses,” said Prokosch, who summed up the conference's key message when he stated, “Our industry, more than many others, is certainly reaping the benefits of all these trends.”

The benefit of cooperative diagnostics

Sebastian Erdmann, the head of Digital Solutions at another KION brand, Hamburg-based STILL, also demonstrated how connectivity can be used in practice, having teamed up with Roman Cunis, the head of IT Service Development at ServiceXpert, to create a system for truck diagnostics. “Previously, when the visiting technician could not immediately detect the problem, it cost valuable time,” noted Erdmann. “And purely remote diagnostics, where defects in forklifts and other trucks are analyzed via the web, are also not ideal since there is no technician available at the customer site to help. But with cooperative diagnostics, a technician can connect in real time with external experts. The ability to connect and share expertise is the only way forward.”

It became clear during the conference that there is plenty of potential for innovation. “Even if the market is sometimes cautious when it comes to innovation, someone has to come along and stir things up,” noted the conference chair, Heiner Sternstein from Linde. “You want to be in a position in 10 years where you can look back on successful ideas and say 'that was the right step to take at the right time'.”