Research leads to discovery

The statement highlights the situation around the "last mile", where many work steps are still characterized by tough physical labor. Deliverers maneuver their vehicles as close to the front door as possible, personally handing over the delivery and they are also busy in the mornings and evenings lifting packages into their vehicles or returning undeliverable goods. After an initial query to Dematic, it quickly became clear to project leads that this is a fundamental problem impacting numerous suppliers from various industries - from the package delivery service in retail trade as well as the supplier of spare parts. Jarr explains that he began doing field research by talking to delivery employees on the street: "It soon became clear that the two hours spent loading in the morning was very common."

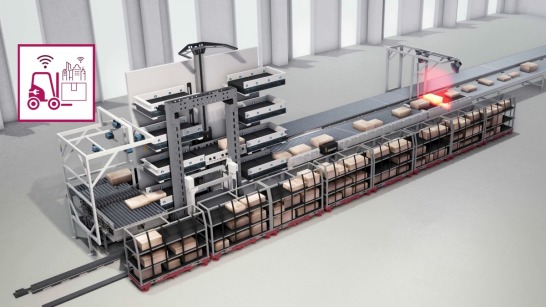

The solution Dematic has developed to address the problem, “PackMyRide”, involves an automated system that can actually take packages off the conveyor belt and then uses algorithms to tightly fill a shelf. Dematic drew partially on various in-house developments. "These are, after all, core capabilities at Dematic," notes Jarr matter-of-factly. "On the one hand, you have 3D packing algorithms, which can also calculate which goods can be stacked on others, and then there's the automated system itself. However, in this case, the challenge was that these warehouse systems usually work with a rather clearly defined product range. They know already which products will come before their robot fingers. In contrast, when it comes to package delivery personnel, the product range can quickly become incredibly broad and it is usually quite random. "You can only determine the data to a limited extent in advance," explains Jarr. Weight is collected by packaging distribution centers as standard; yet, other data, such as size or stability, is not collected, or just to an insufficient degree and too late in the process. "So we had to teach the system to re-measure itself."

Good things come from blank sheets of paper

Next, the system had to learn how it grips and positions different-sized products. The question of the best gripping technology for robotic arms is one that countless engineers and companies have been looking into. Not surprisingly, the answer is that it depends on what exactly needs to be gripped. "However, in this case, it was also a question of how best to sort the package," notes Jarr, adding, "Imagine a large robot gripper arm that is supposed to sort a 10-centimeter small package into a standard bookshelf in the open gap next to a larger package. The gripper would be much too large for this, which is why with 'PackMyRide', Dematic decided on a concept based on very thin fingers that can push packages into narrow openings using a ‘flat hand’ type of movement."

All this was created on the proverbial "blank sheet of paper process". As Jarr puts it, "In the beginning, we had something like 50 to 100 ideas and then we split up into teams that competed against each other for a while," he says. In the end, they came up with about six solutions whose strengths were weighed against each other, leaving the one now known as ‘PackMyRide’ standing alone.