Automation

The path from Industry 4.0 to Industry 5.0: How the KION Group is driving forward the automation of global supply chains

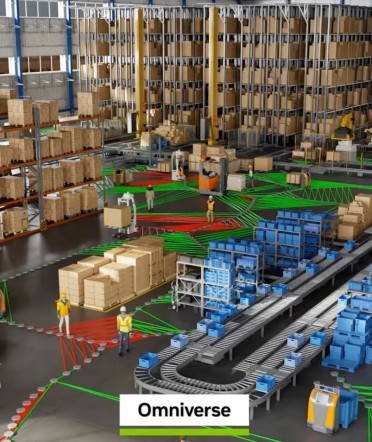

The KION Group is undergoing a profound transformation: We are increasingly evolving from a leading hardware provider into an innovative software company and a pioneer in intralogistics automation. Our focus is on the research and development of future-oriented automation processes for efficient and fast operations in modern warehouses and logistics centers.

Today, end-customers expect fast deliveries, often on the same day (Same-Day Delivery). This demands a significant acceleration in warehouse operations, seamless goods handling, and drastically reduced delivery times through optimized outbound processes. Simultaneously, available spaces for new warehouse locations are shrinking in conurbations and major cities. The solution: Intelligent automation solutions from the KION Group, enabling maximum efficiency even in minimal space.

Tailored Automation for Every Requirement

We offer every customer precisely the logistics automation that meets their individual needs. From the integration of individual autonomous vehicles to the establishment of a fully automated high-bay warehouse – our solutions are flexible and scalable. Especially for urban environments, we develop compact, automated warehouses that require minimal space.

Advantages of KION Automation Solutions:

- Scalability: Easy expansion with additional modules.

- Efficiency: Optimization of material flow and process speed.

- Adaptability: Solutions for every operational size and industry.

- Future-Proofing: Preparation for evolving market demands.

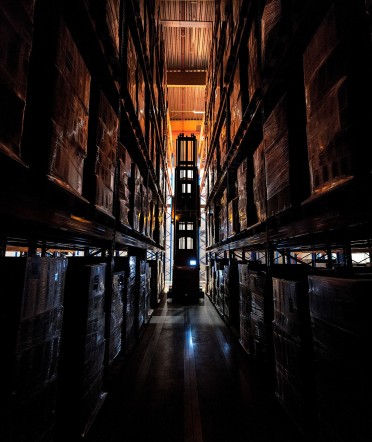

The pinnacle of our automation solutions is the so-called " Lights-Out Warehouse " – a fully automated warehouse that can theoretically operate 24/7 completely without lighting, as all processes run smoothly without human presence. Modern distribution centers have thus become true high-tech masterpieces, controlled from intelligent control centers.

Automated Racking Systems in Focus for Warehouse Optimization

Automated storage and retrieval systems and sorting systems are the KION Group's answer to the increasing demands for speed and accuracy in intralogistics. Our subsidiary Dematic integrates various racking systems as central components of comprehensive solutions for automated warehouses.

A warehouse offers numerous opportunities for process automation:

- Automated goods receipt

- Digital pallet inspection at inbound

- Intelligent transfer points

- Conveyor technology with integrated scales for weight control before dispatch

- Automated Truck loading

The selection of racks for industry is diverse: Shelving racks, pallet racks, wide-span shelving, cantilever racks, and other specialized industrial racking optimize internal transport of pallets, containers, trays, boxes, and cartons. Optimal space utilization in the warehouse is a crucial factor for the future of intralogistics.

Micro-Fulfillment Systems: The Solution for Urban Space Constraints

Especially in major cities and conurbations, available spaces for warehouses are scarce. This is where Micro-Fulfillment Systems come into play – a perfect solution that saves time and space:

- Fast Order Assembly: Complex online orders and shopping carts are fully automatically picked and packed within a maximum of one hour.

- Compact Design: Requires only approx. 900 square meters (approx. 9,687 sq ft) of space.

- Location Flexibility: Ideal for integration directly behind retail stores, supermarkets, or as a standalone micro-warehouse in the city.

This close proximity to the end-consumer or their pickup station reduces delivery times, increases customer satisfaction, and boosts the profitability of online orders. For the food retail industry, our systems can be adapted to different temperature zones, including storage and picking of frozen products. For the fashion and retail industry with high product turnover, many changing items and huge quantities, innovative solutions that reduce warehouse space and increase productivity are a key to success. Connectivity with Dematic Software also enables full data control and seamless integration into existing merchandise management and ERP systems.

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs): Intelligent Mobility in the Warehouse

Automated Guided Vehicles (AGVs) represent a rapidly growing market in intralogistics, where the KION Group is one of the world's leading providers. These autonomous vehicles optimize automated material flow from inbound to outbound.

Autonomous Mobile Robots (AMRs) are an evolution of traditional AGVs. Unlike rail-guided systems, AMRs navigate intelligently and flexibly through the warehouse. They create their own maps of the environment and can dynamically circumnavigate obstacles, significantly expanding their application possibilities and efficiency in constantly changing warehouse environments. They are ideal for flexible material transport and support dynamic adaptation to new requirements.

Advantages of KION AGVs and AMRs:

- Software-Driven Precision: Control, traffic rules, battery monitoring, and fleet utilization can be optimized via software.

- High Safety: Comprehensive safety systems to protect personnel.

- Interoperability: KION, through its STILL brand, actively collaborates with associations like VDA and VDMA on the VDA 5050 interface, ensuring cross-manufacturer communication of AGVs and control systems to prevent compatibility issues.

Dark Warehouse, Lights-Out Warehouse and Always-on Operations: The Pinnacle of Intralogistics Automation

The KION Group offers a comprehensive range of solutions: From communicating industrial trucks to automated order pickers and storage systems, and integrated software solutions. All of this makes our customers' logistics chains more efficient, faster, and smarter – and adaptable to future demands.

In the "Lights-Out" warehouse, driverless vehicles, automatic racking systems, and robots work seamlessly together. All functions of warehouse logistics operations are automated, with robots performing the work while humans manage the overall processes. Machines and technology not only handle monotonous tasks but also make autonomous decisions based on collected data and analytical capabilities. The result is "automatically" higher efficiency and speed, as well as significant energy savings due to reduced or extinguished lighting.

Frequently Asked Questions (FAQs) about Intralogistics Automation

Q: What is intralogistics automation?

A: Intralogistics automation refers to the use of technologies such as robotics, Automated Guided Vehicles (AGVs), automated racking systems, and software solutions to optimize and accelerate processes within a warehouse or logistics center. The goal is to reduce manual tasks, minimize errors, and increase the efficiency of material flow.

Q: What role does the KION Group play in automation?

A: The KION Group is a globally leading provider of solutions for intralogistics automation. We develop and integrate hardware and software for automated warehouses, Micro-Fulfillment Systems, Automated Guided Vehicles, and holistic automation concepts.

Q: How do Micro-Fulfillment Systems help with space constraints in cities?

A: Micro-Fulfillment Systems are compact, highly automated storage solutions ideal for urban areas and conurbations. They require minimal space (approx. 900 sq ft) and can be directly connected to existing retail stores or located as standalone micro-warehouses in the city to enable Same-Day Delivery and fast picking of online orders.

Q: What does "Lights-Out Warehouse" mean?

A: A "Lights-Out Warehouse" is a fully automated warehouse where all logistical processes are handled by robots and automated systems without human presence. Since no lighting is required for humans, it can be turned off or significantly dimmed, leading to substantial energy savings.