For anyone who approached the joint exhibition space, it was obvious at a glance that Dematic and Linde Material Handling were two brands acting in concert. A consistent design concept — on one side in Dematic yellow, on the other in Linde red — connected the two booths as a combined unit. However, both brands are not only united by their strong brand presence at MODEX, but also by their common ambitions: Dematic and Linde Material Handling both provide customers with customized floor-to-store solutions and both are backed by a proven track record of exceeding customer needs and expectations when it comes to material handling.

Safe and scalable solutions for every requirement

Dematic and Linde Material Handling invited MODEX attendees to experience interactive zones tailored to solutions for the grocery, apparel, food and beverage, and general merchandising industries. At the Linde booth, the new Linde Series 1252 Electric Counterbalance Truck and the Linde Series 5215 Reach Truck made an impressive appearance. In addition to high-performance trucks with forward-looking drive technologies, the KION subsidiary also presented a smart operator assistance system, Linde Guardian, which uses portable units and full-service awareness technology to monitor internal traffic. The system can see around corners and be programmed to safeguard against hazardous scenarios involving trucks, infrastructure, and people.

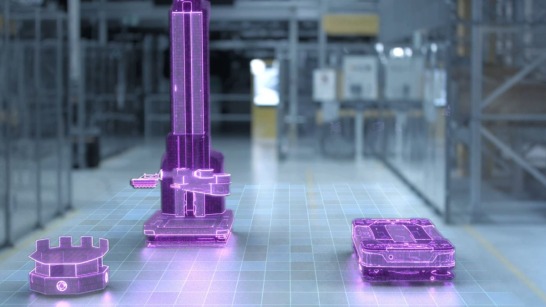

Another highlight was Linde Scalable Forklift Automation, a new mobile automation solution. It is especially designed for low-level order picking and uses automated guided forklifts — such as P-MATIC and L-MATIC for automated horizontal transport, the R-MATIC and K-MATIC for vertical storage and retrieval solutions. These forklift solutions are highly scalable and can be adapted to the specific requirements of each operation. “We are elevating our Linde customer portfolio from Linde forklifts to digitalized Linde forklifts,” says Noe van Bergen, Director Automated Solutions at Linde Material Handling / KION North America. “We are making mobile automation much more accessible to the mainstream market. And interacting with our customers on a different level also closes brings us closer to our sister company Dematic.”

Two logistics experts, one integrated offering

Linde Material Handling and Dematic cooperate extensively to offer customers a comprehensive range of automation solutions. To provide a fully automated supply chain, Dematic complements the Linde Material Handling range of mobile automation solutions with order picking, transport, and storage systems. “With the integrated offerings of Dematic and Linde Material Handling in one harmonized platform, customers can address nearly every application need at a one-stop shop. This reduces complexity, decreases lead times, improves safety, and enhances productivity,” said Jonathan Dawley, President of KION North America.

“Our approach is to look at where our individual customers start their automation journey and how we can help them with their challenges. With Linde as our partner next door here at MODEX, we can showcase how we can take the journey from early automation with our forklift partner all the way to very complex solutions including software and combine all of these solutions for our customers,” said Mike Larsson, Dematic Americas Executive Vice President.

Smart software meets state-of-the-art robotics

At the Dematic booth, visitors could get first-hand information on Smart Task Activation, Dematic’s order fulfillment management software technology that increases operational effectiveness. “To synchronize workflows in real time, it uses a dynamic strategy based on a revolving queue of orders,” said Larsson. “The software ‘pulls’ work to resources and processes orders on-demand, continuously and dynamically instead of following a pre-defined, inflexible plan.”

Visitors were also able to get a taste of Dematic's robotics solutions, for example Dematic Mixed Case Palletizing. This system provides dual functionality, depalletizing inbound inventory on one shift and palletizing outbound orders on the next shift. As a flexible solution for transporting goods, Dematic presented a family of systems for automated load transport within a facility, including a wide range of Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs). Extensive information on other Dematic solutions such as micro-fulfillment supplemented the diverse trade show exhibits of the two brands. For visitors, MODEX was a great opportunity to experience the KION Group's entire solution expertise in one place. And a perfect introduction to the fact that they will be able to get the entire solution portfolio from a single source in the future.