What gives you confidence about the current development of the supply chain solutions in China?

In China, we believe in three success factors: the right time, the right location and the right people. These factors are also part of our “Growing in China” strategy:

Take the time factor, for example: China is currently experiencing a growth phase in automation for intralogistics processes. Over the past ten years, the market for warehouse automation here has grown by around 20 percent on average. When it comes to logistics automation, however, the penetration rate in China currently only stands at around 10 percent, compared to a rate of 60 to 70% in the developed markets in Europe and the US. This market therefore offers huge development potential.

Now let’s consider the location factor: The Chinese intralogistics market has continued to evolve in recent years. The combination of logistics infrastructure, intelligent technologies and a suitable environment for investment means that there are outstanding location conditions.

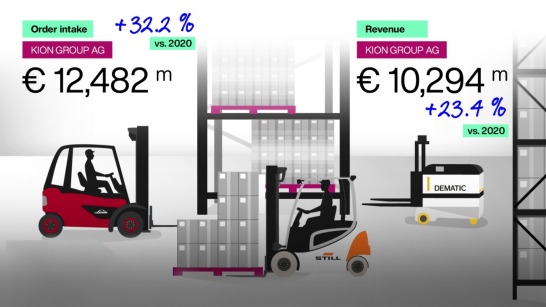

Finally, let’s look at the people factor: Dematic has been doing business in China for more than 20 years and has a highly professional team. Besides, the great support from the Dematic’s international team, the parent group KION as well as the anchor investor Weichai has provided us with the ideal conditions for success.

What are the reasons behind the fast growth of the Chinese market, including in regard to Europe and the US?

I would like to talk about three special features in China that we recently identified in extensive market surveys:

First, our clients essentially tend to be more medium-sized Chinese enterprises who are not yet known internationally, as opposed to the large listed groups we work with in Europe and the US. However, these local companies in China, of which there are many successful examples, are particularly in need of automation solutions.

Second, the Chinese government is making a big drive toward Industry 4.0 as part of the “Made in China 2025” strategy. And, of course, this also affects intralogistics. The intelligent production industry that the Chinese government is aiming for offers us a huge opportunity.

In addition to this—in contrast to Europe and North America—the competitive environment in China is highly fragmented. The market share of the five leading companies in the supply chain solutions sector, to which Dematic belongs, is less than 20 percent. That said, there are lots of local companies and startups that are reacting quickly to the evolving market. Their innovative capacity and ambition should not be underestimated.

How does Dematic intend to continue to grow in light of these peculiar features of the Chinese market?

Put brief, by consistently implementing our local strategy. We can’t simply replicate our experiences from the West in China, rather we need to think from the perspective of our local customers so that we can implement forward-thinking products and technical innovations that are tailored to the Chinese market.

What’s more, we need to react quickly to the needs of the customer. KION built and commissioned its forklift truck plant in Jinan in just over a year—that’s Chinese speed. At Dematic, we will continue to improve process agility in order to keep ahead in the face of tough competition.