It is this transition – from standard truck to intelligent vehicle – that defines the location. But Antwerp stands not only for technological progress, but also for a special kind of cooperation and flexibility: “Our strength in Antwerp is recognising the needs that come in through the Operating Units early on and responding flexibly to them. We can implement changes very late in the process – that is exactly what gives us speed, especially when the requirements are very specific,” says Van Orshaegen.

One roof, one rhythm

Around 350 employees make Antwerp our Centre of Excellence for automation in the EMEA region. For Frank Heptner, Vice President Co-Lead Automation EMEA, the location stands for a new kind of cooperation: short distances, bundled expertise. The fact that development, engineering, testing and commissioning work side by side here has a noticeable effect on speed and quality: “I experience an intense sense of togetherness here in Antwerp,” says Heptner.

"Sharing a single space with our sister companies is a great opportunity for all of us," agrees Farly Orie, Market Leader Benelux, Dematic. "The closer proximity enables us to work more closely, learning from each other and gaining a better understanding of how the other brands operate. Customers also benefit significantly from this collaboration. Within KION, we provide automation solutions across the spectrum, from manual applications to integrated complete systems, and the specialists for all these offerings are now united in this office. Automation, after all, is deeply embedded in Dematic's DNA; our decades of experience in this field make our integration into the Centre of Excellence a perfect alignment.”

From series production vehicle to solution

Every project begins with what is known as solution design: a team of around 15 specialists translates the customer’s requirements into a concept. This involves determining which processes are to be automated, which vehicle types are suitable, and how they fit into the existing environment.

This is followed by engineering – around 70 engineers work on the detailed design and selection of materials. “This is where the actual vehicle design is created, right down to the cable harnesses, safety systems and vehicle control,” explains Van Orshaegen. Special solutions such as conveyor belts or clamps are also integrated at this stage.

Once the vehicle has been built, commissioning begins; testing, validation and software adjustments before the solution is handed over to the customer. Only when all processes are running smoothly, and safety approvals have been obtained does real-world operation begin. “Our process therefore extends from the first stroke on paper to handover to the customer – all under one roof,” summarises Van Orshaegen.

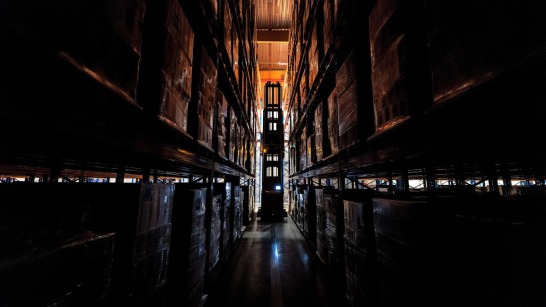

Special solutions that open doors

Antwerp speeds things up where traditional series processes would be too slow. One example is a heavy-duty forklift that can move several pallets at once – for the beverage industry, for instance. Or a specialised heavy-duty forklift for a Swedish car manufacturer, which was tested and customised in Antwerp.