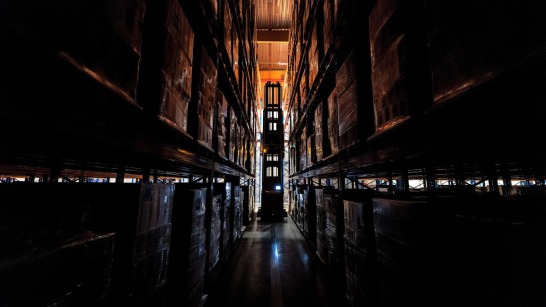

Dark, Lights-out, Always-On: How warehouse operations are setting the pace for modern supply chains

Fully automated storage systems can operate without personnel and thus “in the dark.” But how far has this technology progressed in practice? And what are the economically viable limits of its use today? A reality check with our Dematic experts.

2025-09-10