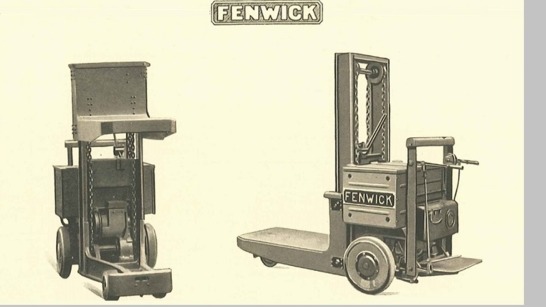

Did you know that the Euro pallet revolutionized warehouse work, that forklifts operators have not always enjoyed unobscured views, and that tomorrow's vehicles will not even need an operatorr? Have a look at ten images that tell the story of the forklift.

The evolution of the forklift in ten images

KION Group celebrated its tenth anniversary in 2016, which is reason enough to reflect on the past. However, we are not talking about just our short past, but the longer one involving how forklift trucks and intralogistics have evolved over the last several decades.

2016-12-20