Linde Rental Service the Perfect Petri Dish for the Lighthouse Project

Refurbishment facilitates a re-use concept, which enables battery use to be maximized. There are also plans to carry out battery refurbishment at KION Battery Systems in Karlstein am Main, the battery's birthplace. For the experts, this raises several questions: How can the battery be assessed quickly and cost-effectively? How intensively was the battery used by the customer? Where is the damage? How extensive is the wear? And how much capacity can still be extracted from the energy storage device? The battery is examined, and its technical performance determined. Based on this diagnosis, a simple or comprehensive refurbishment then follows. The process takes just a few days to complete, and afterwards it is hard to tell the difference between the refurbished battery and a new one.

The battery pool of Linde Material Handling Rental Services GmbH was selected in the search for a suitable testing ground for the refurbished energy storage devices. Li-ion batteries and electric forklift trucks at the rental and leasing business remain the property of the KION Group. This means that the team has easy access to battery systems. This provides the necessary framework that enables KBS experts to gain important knowledge and experience regarding the refurbishment process. The experience amassed as part of this process will pay dividends in the long term, with the use of refurbished batteries set to become much more widespread in the near future.

Sustainable Vision of the Future: Refurbished Batteries in Refurbished Forklifts

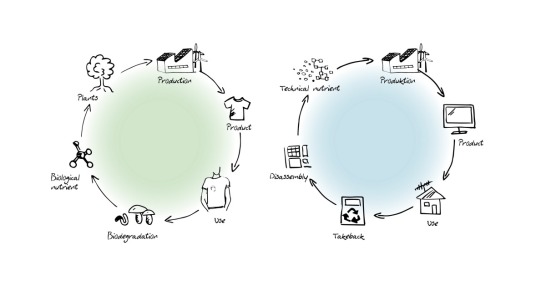

The sustainable cycles being tested as part of this project are set to be scaled up in the long term. Going forward, they will also be put to use in a range of areas, including one in which the KION Group has already amassed experience over the years, i.e., industrial truck refurbishment. In Poznań, Poland, for example, the KION brand STILL has been restoring used forklift trucks, pallet trucks, and warehouse trucks to almost-new standard since back in 2011. Buckled metal is fixed and rewelded, worn tires are replaced and a new coat of paint is applied—a time-consuming process carried out with a great deal of know-how. The advantages that used forklifts like these offer customers are obvious: lower price points, immediate availability, and high quality. It’s a similar story in Velké Bílovice, Czechia, where—at its 14,800-m2 Remanufacturing Center—KION brand Linde MH EMEA refurbishes more than 5,000 trucks each year and also equips them ex works with extra features (e.g., the Linde Blue Spot warning system) at the customer's request, bringing real added value to the customer base.