On a Thursday evening, Axel Hölzlwimmer, a first-year trainee in the mechatronics group at STILL’s Munich location, received an unusual call. Beginning Friday, his training would move to his home. ‘Remote training’, or learning from home, was on the agenda from this point onwards. Instead of him making his usual morning commute to the site, he would remain at home. Yet he was not the only one; it was the fate of almost 270 trainees and dual students from KION subsidiaries, Linde Material Handling and STILL, throughout Germany. And it was the same fate for their trainers, who were also to remain at their desks at home with laptops at the ready as part of the protective measures to contain COVID-19. Indeed, it came as a surprise and it was a considerable interruption to the daily life of all involved.

The situation brought several challenges to everyone in charge of training at the respective KION brands: How do you coordinate the hordes of inquisitive young professionals-to-be when you must do so from home? How do you explain content from a distance that you would normally have shown directly at the forklift? Under these conditions, how do you best prepare the examinees for their final exams and assignments?

Creating a theoretical foundation for practical challenges

These were just some of the questions the trainers from the various business areas at Linde Material Handling and STILL had to tackle pragmatically, purposefully, quickly and most importantly together. The solution to the primary goal of knowledge transfer was quickly clarified: e-learning combined with intensive support. "At the beginning, this was naturally an unfamiliar situation for everyone; for the trainees as well as for us. It was entirely new terrain," explains Christopher Lorenz, trainer for the mechatronics group at STILL in Hamburg. "Even though it involves a lot of effort since we are in close contact with every trainee daily, we see that there is a high level of motivation from both sides." The trainers from both brands exchange learning materials and can thus offer a comprehensive package to all trainees.

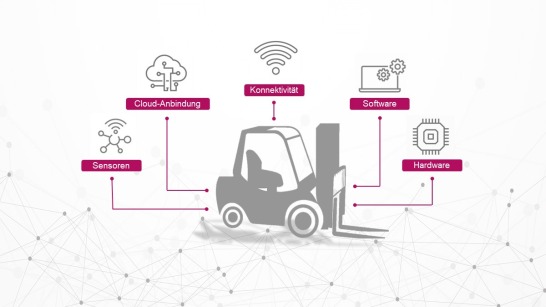

With the help of the appropriate online tools, the training years were quickly allocated and organized into groups. On the agenda: Various learning units ranging from basic knowledge for the specialist area, specific product launches by the individual brands to cross-topic units on lithium-ion technology. "Initially, it was a strange feeling to settle into a monotonous desk job instead of physically moving around the shop floor," admits Hölzlwimmer on the transition to home office. "Even though it is rather unusual to work on so much theory at once, you can see that we are learning important basics here, creating the groundwork for what we can later apply in practice. What we are learning has a purpose in the real world."

The trainers also make sure the youngsters do not get quickly bored despite limited opportunities: "We try to offer as much variety as possible," confirms Jean-Christopher Klix, the head of Vocational Training at Linde Material Handling. It also includes incorporating a little practical entertainment between the numerous theoretical units: Christopher Lorenz's trainees received an interactive learning kit, which included a micro-controller, which is a small single-chip computer system where they must write a program to make the integrated LEDs light up. "You see, they can tie in with the programming language they learned in electrical engineering and they can actually experience their small accomplishments first-hand."