Digitalization

News from KION on the Digital Transformation in the Intralogistics Sector

As one of the most important megatrends of our time, the digital transformation is changing our very way of life – and way of working. This is especially true for intralogistics: Thanks to our intelligently networked and flexible intralogistics solutions – ranging from stand-alone software to fully automated warehouses – we at the KION Group want to drive digitalization in logistics and the automation of the material handling sector forward, and thus play a major role in laying the groundwork for Industry 4.0 . Our teams of software specialists are developing innovative digital technologies for the logistics industry around the world – be it in Europe, Asia-Pacific, or North and South America. To ensure we offer our customers the best possible package, we are developing innovative, digitally networked solutions. On top of that, we are also digitalizing our own internal processes and bringing pioneering development methods such as “Agile Invention” to the intralogistics sector.

Digitalization at KION: Evolution from Hardware Company to Software Company

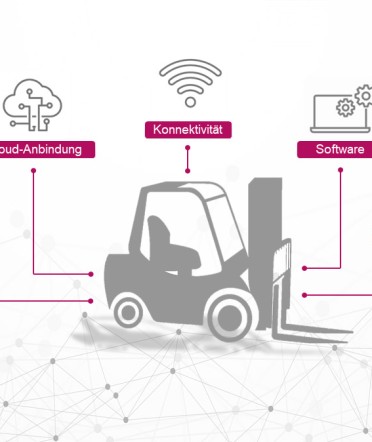

The KION Group is consistently focusing on connectivity and processing large amounts of data (big data & analytics) in real time ( 5G and beyond ). It is clear to us that future success depends on innovative software. As a complete solution provider, we want to create significant benefits for our customers. And that means KION is increasingly evolving from a hardware to a software company.

One example of this is the acquisition of the British software company “Digital Applications International Limited” ( DAI ), which specializes in logistics applications. Together with DAI, KION subsidiary Dematic is expanding its digital offering in order to support transportation, storage, and goods distribution across the entire supply chain. It is this interplay between cutting-edge hardware and software that gives our customers an enormous competitive advantage. DAI has incorporated its industry-leading logistics automation software into the warehouse management system provided by Dematic . This has allowed Dematic to offer its customers a complete solution package for fully automated, semi-automated, and manual warehouses as well as across the entire supply chain.

Logistics News in the Field of Digitalization

From Networked Forklift Trucks…

Automated logistics trucks are the future of efficient material flows. They take over tiring transport tasks from employees, increase the handling volume, and reduce the error and accident rates in the warehouse. Hundreds of thousands of trucks from the KION brands Linde MH , Fenwick , STILL , Baoli , OM, and Dematic are being used everyday around the world to ensure that items are transported from the warehouse entrance to their designated storage location. In a networked warehouse, there are many different data streams that are systematically recorded and processed. For example, automated guided vehicles are equipped with modern sensors, such as laser scanners and cameras, to enable them to safely navigate their way through racks, production lines, and warehouses. During operation, they continuously generate vast quantities of data relating to their surroundings.

We help our customers collect the data recorded by these high-tech networked industrial trucks and warehouse systems , pool the data using a cloud-based solution , analyze the data and optimize their processes ( digital twin ). Using these cloud-based solutions, warehouse trucks and forklift trucks can inform service technicians when a repair is needed, or automatically alert them to upcoming maintenance. Software updates can also be installed and the truck itself can be adapted to changing customer requirements. Ideally, all trucks are networked with each other. This has numerous advantages for the customer: Servicing, remote diagnosis , and preventive maintenance all increase truck availability and help to reduce costs.

...To Networked Fleets...

On a larger scale, these data streams allow for greater transparency with regard to the capacity utilization of the entire fleet. Which forklifts are currently in use, which were under-utilized last month, and where could more efficient routes be planned? When does which truck need recharging and how can it do this without having to queue, without disrupting its work, and without overloading the power grid? If you want to manage your fleet, you usually want to do it across all locations – and preferably in real time. Fleet management systems such as STILL neXXt fleet and Linde Connect will process and analyze the data. We are also working with the software specialists at ifesca to provide AI-assisted energy management for electric forklift truck fleets.

...To Networked Warehouses.

At KION, we like to go one step further: What if we could use the data collected to create high-resolution 3D maps of the warehouse or production facility? This live information would make it possible, for example, to simulate the routes of the different trucks and thus improve the processes in the warehouse or in production. These smart and digital services can also help detect and report anomalies such as blocked travel paths. If this is done consistently, the overall structure of a warehouse can ultimately be optimized. This is where the research project ARIBIC comes in, which is being spearheaded by STILL – a subsidiary of the KION Group. The data collected by the sensors on the trucks is used to create high-resolution 3D maps of warehouses or production environments. The aim is to create a digital twin of the environment, so that relevant data can be displayed and shared in real time, and production operations improved.

Digitalization in Logistics: The Networked Warehouse of the Future Requires a 5G Network

The more data that is collected and processed, the more important it becomes to have a fast, mobile, and reliable internet connection. KION is therefore pushing for the further development and use of 5G, a mobile communications standard that allows for data transmission at speeds of up to 10 gigabits per second – which corresponds to a network capacity that is 1000x greater than LTE. There are high hopes for 5G when it comes to Industry 4.0 and the networking of various machines and systems. The main advantages are the aspects relating to performance and reliability: Real-time data transmission is important wherever large numbers of devices are networked and communicate with one another within a small area – for example controlling driverless transport systems in indoor logistics environments. Another important aspect for intralogistics is the low power requirement. 5G allows for communication that is highly energy-efficient with regard to assets such as batteries and accessories. Energy consumption can be as low as one tenth of 4G, which is highly beneficial for mobile systems in particular. 5G network coverage has not yet been established across the board, but KION is involved in various research projects so that it can be at the forefront of 5G developments in intralogistics.

Artificial Intelligence and Virtual Reality Are Revolutionizing Intralogistics

The KION Group is also pioneering VR solutions and AI applications in the intralogistics industry. An example of this is our collaboration with the Fraunhofer Institute for Material Flow and Logistics (IML), which focuses on a new generation of autonomous transport vehicles that are set to revolutionize the intralogistics industry with artificial intelligence (AI). The big paradigm shift for this technology is that, for the very first time, artificial intelligence is being used for traffic management. The robots communicate with one another via 5G, independently coordinate their routes, and are also able to autonomously accept and deal with orders. This makes the LoadRunner® swarm robot the first technology to combine the capabilities of powerful sorting and conveying technology with the potential of autonomous AI-based systems.

In contrast, virtual reality (VR) is being used, for example, in product development to bring the prototype of a new industrial truck to market maturity even faster using digital 3D models. The KION Group is also using 3D models for customer appointments and digital events. For example, the KION subsidiary STILL offers an interactive showroom , which allows the customer to experience and interact with a forklift truck and its operator’s cab by rotating a tablet through a 360° view. Dematic’s TechCenter , which showcases innovative products and solutions in an automated warehouse, can also now be accessed as a virtual 3D tour at home.

_image_737x414.jpg)

_image_372x442.jpg)

_image_372x442.jpg)