KION Subsidiary Dematic Takes Cradle to Cradle® Approach in Important Steps Toward Circular Economy

Product design has always been a challenge. But in recent years, the bar has been raised even higher by the pressing requirement to keep the impact of products on the environment to an absolute minimum. With a New Green Deal agenda and the Circular Economy Action Plan, the European Union (EU) has already announced a number of measures that are designed to help Europe achieve climate neutrality by 2050. KION subsidiary Dematic is taking an important step toward this more sustainable, climate positive future by embracing the Cradle to Cradle approach in rethinking their products in terms of material safety and recyclability (making them more circular).

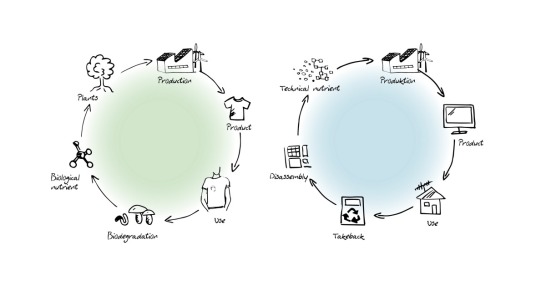

Source: Braungard/McDonough; © EPEA GmbH – Part of Drees & Sommer

2022-08-10